To increase profit margins and provide a better customer experience, more and more companies are outsourcing pieces of their supply chains and expanding supplier networks all over the world. This often results in an incredible complexity of supply chains going hand in hand with dispersed data across internal systems, a lack of control over outsourced logistics processes, and poor stakeholder communication who are involved in such diverse supplier networks.

To mitigate such risks, companies seek to ensure visibility at every level of their supply chains. But where to start? In this blog, we explore the value of end-to-end supply chain visibility and share insight into how modern data connectivity solutions can help bring transparency to the most complex supply chains.

What is supply chain visibility, and why is it critical?

Supply chain visibility (SCV) aims to collect better information about supply chain operations to improve process efficiencies, reduce risks, and increase business profits.

It is not a secret that for many large businesses, most inefficiencies occur due to poor visibility in their supply chain rather than from their own operations.

Suppose a product you produce has 100 parts, which is often the case for businesses such as manufacturers, and in your warehouse, you have only 99 of them. So, while you are missing the last crucial part, you cannot assemble the product and have it ready to sell. With no information from your supplier on when this essential piece will be delivered to your warehouse, you cannot plan production and provide your clients or partners with estimations regarding product availability.

You can back up a double supply for each component or enlarge your inventory to ensure production. But are these rational solutions? Of course not. You need to improve your supply chain visibility. This way, you can get valuable information from your suppliers in real-time and take the right actions based on this insight.

Supply chain visibility allows tracking different goods and/or products in transit, giving a clear view of where your stuff is to plan the inventory and production activity. Also, it enables businesses to improve customer service and cost controls through better inventory in motion management and proactive status updates from suppliers.

If the business from our example would have SCV enabled, it could track components or sub-assemblies as they travel from suppliers to their warehouse to spot and fix inventory shortfalls before they become a significant problem. Also, it would allow the company to track movements and inventory of ready-to-sell goods and products. Which would positively affect business relations with partners, improve customer service, reduce costs, and enable a stronger supply chain through better decision-making and automation of critical business processes.

Although SCV is vital for any business that relies on a diverse network of suppliers or has a complex supply chain architecture, achieving transparency at every level of a supply chain is a challenge.

Key challenges of supply chain visibility

SCV is a term that has been around for many years. However, few organizations can brag about achieving complete supply chain visibility.

In essence, visibility within a supply chain means tracking and digitally exchanging/sharing information on supply chain activities to better plan actions or react to any possible problems. Data from quotes, purchase orders, invoices, order receipts, bills of lading, proof of delivery, etc., and constant status updates on a cargo movement, play a critical role in this process. The biggest problem is getting all that information from all relevant legs (from supplier to the first mile to the last mile) and internal systems (frequently dispersed) together to make it available in the right format, time, and place. The cause of this problem is a lack of supply chain processes automation, differences in the technology and data formats involved companies rely on, and the absence of required technical skills and knowledge companies needed for this task.

Some industry players still manually process the documentation and supply chain information helped by spreadsheets such as Excel or Google tools, sending it to business partners via fax or email. Others rely on EDI, a badly outdated and inefficient technology that requires a lot of resources and knowledge to manage the data.

Of course, there are digital champions (digitally advanced companies) who try to use the latest technologies in the domain. However, they all still need to deal with partners who don't have the same level of technological advancement. This means they still must deal with all those emails and faxes, plus hundreds of possible variations of the EDIFACT format to make EDI-based messages digestible for their API-based home-grown solutions. And even though they have everything to bridge the gap between the old and new world, there is one big issue - EDI allows them to receive only a status update upon reaching certain milestones or when some event has occurred. What's happening between all of those is still a black hole.

Also, companies might have siloed systems not designed to work together and exchange information. A good example is when businesses rely on EDI or even some real-time-visibility solutions to process purchasing (for supplier communication) or sales (for customer communication). However, none of those can be leveraged for SCV purposes since they are not integrated with the supply chain element anyhow.

To better demonstrate how all these complicate a business, let's look at a real business case Youredi experts have dealt with recently. In this example, we have an EU-based furniture manufacturer that must deal with B2B shipments of components from Asia to Europe. (NB! The workflow will be similar for any importing business, wholesaler, or manufacturer from any other business segment).

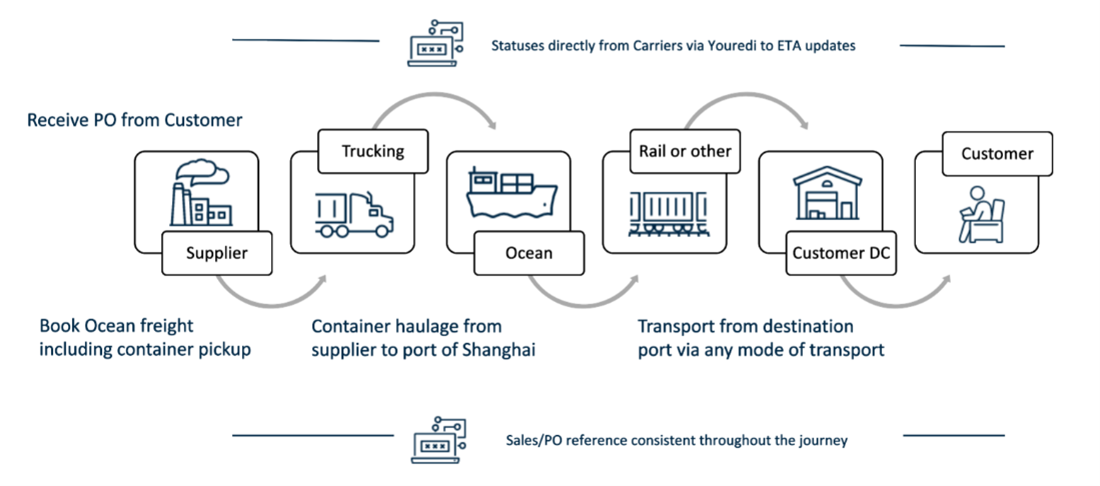

When the company needed certain components or a piece of furniture to place an order to their suppliers, they followed the workflow outlined below:

- When the company receives a purchase order from a customer, it sends purchase orders for a piece of furniture or elements needed to an Asia-based supplier

- The supplier starts production of the ordered items

- When it is ready, it sends an advance shipping notification to the customer (The manufacturer)

- Also, the supplier books an ocean shipment to deliver the order to the manufacturer (typically, suppliers make bookings directly with a logistics service provider)

- When the shipment arrives in the EU, the manufacturer needs to book trucking/vessel/rail or another mode of transport to get the shipment to its warehouse

- When the shipment is at the warehouse, the manufacturer either puts it on the work schedule for the final assembly of the ordered product or prepares it to be delivered to the final customer.

Although the process looks straightforward, there is a big problem with visibility on the step between placing a purchase order to the Asia-based supplier and loading it to the ocean carrier (vessel). So, the case company did not have any information on where the shipment was until it arrived in the EU. Thus, they could not efficiently plan and act.

Many importing businesses, wholesalers, or manufacturers from around the globe have a similar workflow resulting in the same visibility issue. Regular updates on shipment status and process integration would enable better planning and customer service for them. But where to start?

How do companies overcome the visibility challenge?

To manage supply chain execution and visibility processes, companies are torn between buying (often several) Logtech platform products or buying an iPaaS license to do the supply chain integrations in-house.

Looking at the visibility platforms and software market today, you can see a few established names helping to reveal what is going on with shipments throughout their way from A to B. Among those are Project44, Fourkites, Shippeo, and Gravity Supply Chain. Please read our blog on the top 8 supply chain visibility solutions to learn more about the benefits mentioned companies provide.

Although all the above companies focus on enabling visibility, they use different approaches and techniques for data collection and tracking. While some rely on web scraping, others try to leverage direct integrations. So, the level of detail you can expect depends on the technology sophistication behind the solution. Plus, instead of complete end-to-end visibility, they might consider only a specific part of the shipping journey (e.g., the transportation part only). By choosing those, you can expect a certain degree of visibility on the shipment movements from where the order starts to the final destination point. Still, you will most likely need more than one solution in your IT stack to get full visibility throughout your supply chain.

Another problem is that due to the one-size-fits-all philosophy vendors tend to follow, those solutions have limited functionality and require a lot of effort and resources to get them properly integrated with the IT/ ERP systems your partners, and you rely on. Not to mention additional investments and resources needed for solution customization each time your company needs to expand suppliers or business networks, add another vital source of data to your system, or address a specific data integration case.

If going with the DIY option and purchasing an iPaaS, you can expect more flexibility. But still, the process requires a lot of resources, both on the labor and tech side, to get it going. All of those make your visibility project not only very costly but risky as well.

The best way to overcome these issues is to partner with a data connectivity vendor focused on supply chain & logistics and providing complete visibility through modern technology, allowing any level of customization - Youredi.

End2End Supply Chain Visibility Through Youredi's Data Connectivity Service

Youredi is not an SCV visibility provider but a leading provider of fully managed data integration services and solutions for logistics and the global supply chain. The solutions we offer combine the benefits of both options above - ready ecosystems and message formats inherent for visibility software and Logtech platforms and a high degree of flexibility and customization native to iPaaS. This way, we have no drawbacks such as high costs and rigid product roadmaps and are guaranteed a smooth and seamless data exchange throughout the entire supply chain.

Our ecosystem includes ready-made carrier integrations from all modes of transport - Ocean carriers from MSC to ZIM, top 30 Air Carriers, leading road & parcel carriers, and leading TMS systems. Our extensive network of partners allows us to efficiently cover all significant steps of the execution and visibility process, from booking requests to transport documents, or from sailing schedules, and tracking events to invoices.

Here are some examples of services Youredi offers to the wholesale domain, retail business, manufacturing companies, or 3PL/4PL.

Would you like to learn more about how we can enhance your b2b integration strategy and ensure visibility for your supply chains? Schedule a demo call with our integration experts here, or send us a message at talktous@youredi.com