System and data integration solutions on organization and processes

By Dr. Rolf Neise, Senior Lecturer at the International School of Management (ISM) and business consultant, former Global Head of Logistics Operations at BAT.

The opportunities offered by the use of comprehensive IT systems integration solutions in today’s business world are immense. Standalone IT systems can be connected, data can be shared in time, and applications can be serviced by multiple users in parallel. Ultimately, these solutions are not only the prerequisite for becoming a data driven company but also for a real collaboration between multiple trading partners.

On the other hand if data sharing or data integration is done in isolation without preparing the organization or adapting the processes, the danger of failure is inevitable. But how must the organization adapt and how should processes be changed to successfully use the available technology solutions?

In a two-part series Dr. Rolf Neise will address these questions to ensure that the use of IT systems integration solutions lead to the desired outcome.

Information Sharing/B2B Integration

Information sharing and more advanced systems like B2B Integration or API Management are radically improving the way companies and their partners do business. It can be applied to almost all the core domains of corporate operational activities, and it is clearly the key to a successful collaboration internally within organizations and externally between partners. Information sharing can nowadays also be considered as a prerequisite to survival in the digital area of Industry 4.0.

In advanced Supply Chains applications in the FMCG or the automotive industry, the exchange of information like inventory levels, forecasting data, and sales trends between trading partners has led to reduced cycle times and inventory levels, a quicker order fulfillment and improved forecast accuracy and customer service.

Knowledge of these successes is widespread, nevertheless there are only a few examples of truly end – to – end collaborations existing. Psychological barriers around information sharing in organizations exist and sometimes there is a real and justified fear that information sharing across corporate boundaries can turn into a competitive disadvantage.

So how to deal with these barriers? How to prepare your organization for a successful, long – lasting relationship with your partners? How to make best use out of the existing IT – systems integration solutions?

Collaboration

The sharing of real time accurate & relevant data is a prerequisite of a trustful collaboration. It can be seen as a first step into a new form of cooperation with partners, and even with competitors. If these activities are done in isolation without adapting organization and processes, the desired success will not be achieved, the danger of a total failure might even occur. But also if this process is not embedded into a continuous improvement culture between all partners, the expected outcomes will be insignificant. An overarching process must apply, a process which expand the pure exchanging of data, a process which should be understood as collaboration.

When talking about collaboration, it goes beyond managing transactions for efficiency to managing relationships for creativity and continuous improvement. The collaborative goal is to work cooperatively together to devise and implement better approaches to solving problems and delivering value preposition.

Collaboration is a continuous process, therefore collaborative improvement initiatives should be implemented to constantly upgrade the company’s culture of collaboration. It is also important to remove resisting forces in the organisation and transform a company’s culture.

Partnership is always a two way road, where each partner is responsible for the success. To do so the ways of working and processes for the partnership should be commonly agreed.

Collaboration does not come from nothing. Just like with any other functioning process, it requires a great deal of effort and commitment from all partners involved. The more structure is behind this process, the better it works.

Learnings to create a sustainable collaboration can also be taken from several industry experiences in the past, like the introduction of CPFR (Collaborative Planning, Forecasting and Replenishment) tools to share information between suppliers and retailers to plan and satisfy customer demands. This approach was clearly process driven and IT focused, what was missing were skilled resources, joint visions, leadership, a common plan and aligned incentives between the partners.

B2B Integration in Practice: Organizational Adaption

The sharing of real time accurate & relevant data is a prerequisite of a trustful collaboration. It can be seen as a first step into a new form of cooperation with partners, and even with competitors. Based on these learnings and on several experiences the author collected in relationship building activities – both internally within a company between different functions (Supply chain functions and other functions) as well as between different trading partners exchanging real – time data and information – the following 9 steps should be taken to develop a trustful and long-lasting vertical collaboration between trading partners (see also Picture 1)1.

Picture 1. A 9 Steps Guideline to Collaborative B2B Solutions in Practice Organizational Adoption.

(1 General learnings of bigger relationship projects are shared here, like the B2B set-up of a collaborative logistics network of carriers, shippers and customers led by the author. Depending on the size of the activity, not all steps have to be implemented – it is essential that the mind-set is changing into a direction to seriously embed IT – systems integration solutions into the organization, supported by management commitment and dedicated teams working on it.)

1. Cultural Awareness: Understand Your Partner

Every form of collaboration requires a change in strategic thinking. It is not sufficient to highlight changes on the operational level, collaboration is a clear game-changer and needs to be thoroughly embedded throughout the whole organization. Before working together you need to better understand your partner, the thoughts and ideas that drive him and the culture of the company. Knowledge is always the foundation of change and the basis of a long – lasting relationship.

Ultimately, this information will underscore the issues, attitudes and processes that need tweaking — and it can inform managers how to best manifest collaborative activities. This is in the first instance typically a senior management task providing the basis of all B2B integration activities. It is also an ongoing process based on mutual trust between all involved employees.

2. Senior Management Commitment

One of the most crucial elements is to have management commitment for the relationship on both sides. Every initiative to share information or to integrate systems between partners has a strategic impact and has therefore to be driven by the Top Management, which is defining the vision of the new relationship based on a business evaluation and on a solid understanding of the partner. The Top Management should also been responsible to further develop these relationships. It is often useful to have a senior manager acting as the Sponsor of the relationship on board-level. It also includes spending sufficient time with the corresponding top level managers of the new partners. By coming together, senior managers from both sides have the potential to make sustainable, mutually beneficial changes.

4. Common Objectives & Targets

The objectives and targets which should be reached by a collaboration, should be developed by all involved partners, based on a common vision defined by the Top Management. This is a multi-functional process covering all hierarchical levels been involved in the relationship. It is also a regular process which needs to be reviewed annually. It should end up in the definition of tactical initiatives like „Improvement areas“ and also concrete projects the teams are working on. It should also be clear to the involved parties, how they participate in the success of an initiative.

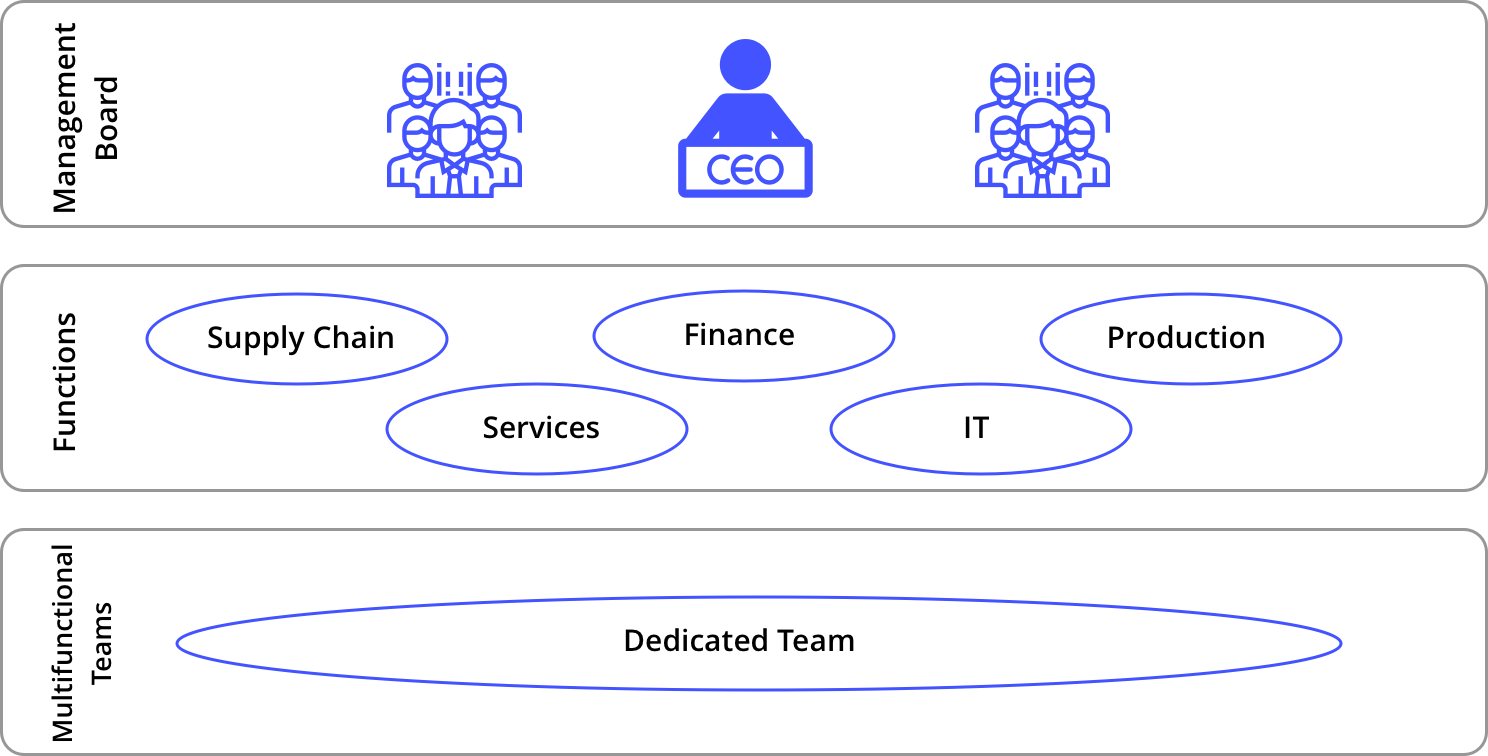

5. Appropriate Governance

An appropriate governance is required and has to be defined. Collaborative relationships can be governed by informal understanding or written contracts.

Trust is almost always a governing principle of winning collaborative relationships. The Governance model includes a clear escalation level process to suspend any misunderstandings. It is often useful to establish an advisory board who is in charge of the relationship, the participants should form the annual strategic meeting (see picture 2. below).

Picture 2. A governance model is a prerequisite for IT system integration.

6. Effective Business Policies and Agreements

By formulating effective business policies, agreements and business plans that a company can use to establish guidelines and rules for exchange of information with supply chain partners and for further collaborative activities the basis of the partnership is laid. This also helps to assuage existing barriers in organizations.

7. A Team Manager Driving the Relationship

On all sides a person responsible for the relationship (ownership) has to be appointed. This could be a Customer Engagement Manager when talking about sharing data with customers or the Supplier Relationship Manager. It is essential that these managers have a good understanding of each other’s business. They should be able to drive the relationship according to the commonly defined objectives forward. These managers are also acting as the advocate for the relationship in their own organizations and the ones who are sharing the success stories.

8. Dedicated Team Working in a Continuous Improvement Culture

A dedicated cross-functional team with those members from the partners who are dealing with the relationship should be established. The size of the team is dependent on the defined objectives and tasks, the team should be led by the appointed relationship managers of the partners. The team should meet regularly discussing any progress, potential obstacles and forthcoming challenges. As this team is the regular body of driving the relationship, a continuous improvement culture should be established. New ideas, further options to collaborate and optimized ways of working have to be openly discussed and commonly developed.

To do so, it has to be ensured that sufficient time is given to the team members to meet and understand each other. This is a prerequisite of a trustful collaboration and it includes common team events and social team building exercises. Trust is the single most important relationship-building factor, it enables cultural transformation.

It is also important to celebrate success stories. Training to develop employees and managers who know how to collaborate and are aware of opportunities to do so should be a permanent part of the relationship. Such investments keep the momentum for transformation alive and promote the behaviors that lead to a real change over the long haul. It will also help to overcome resisting forces in the organization and support risk averse employees.

9. Commonly Defined Processes & Ways of Working

• Business Calendar

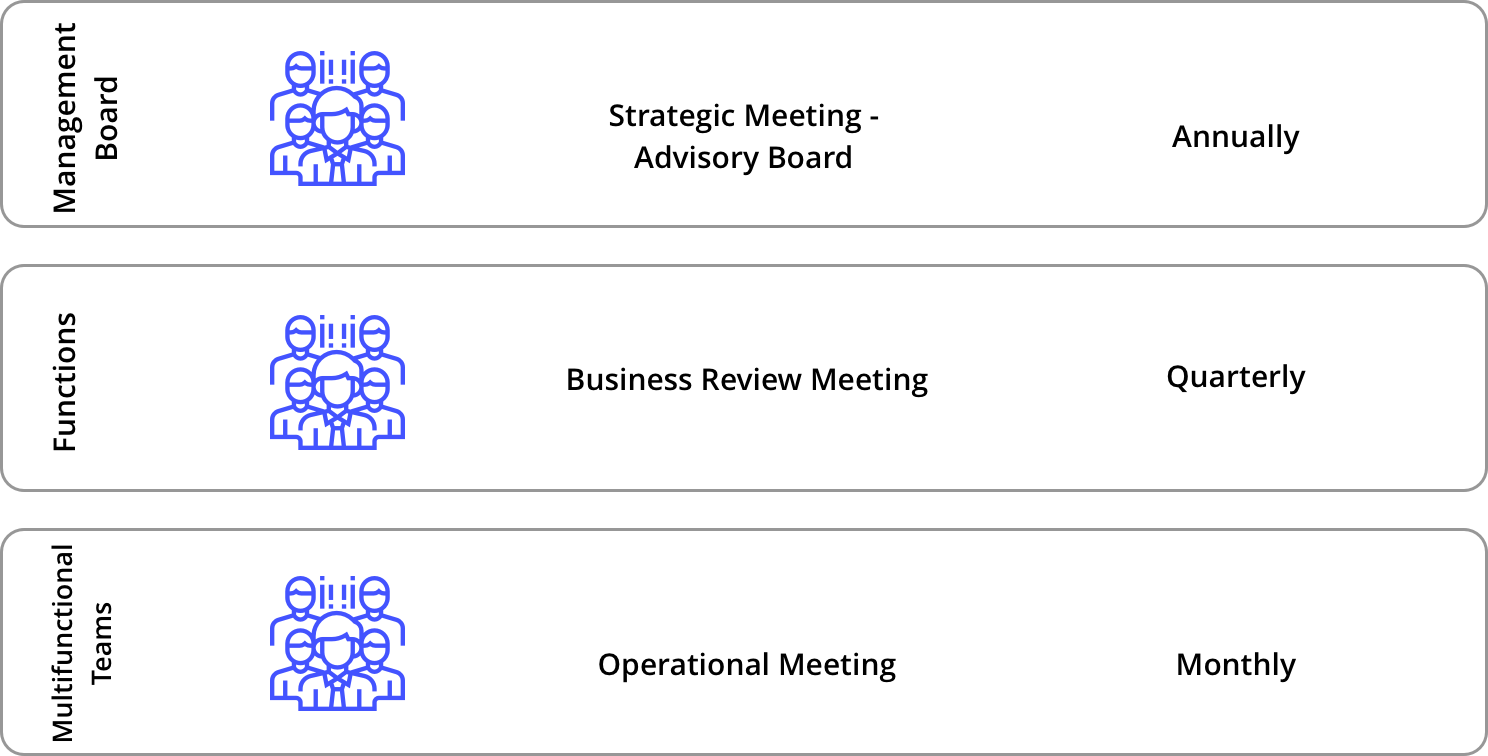

Between all parties a Business Calendar should be commonly developed including the following meetings (see also Picture 3):

- Annual Strategic Meeting (to align priorities and give business direction. This is a typical senior level meeting with management executives from both sides. It should be led by the management sponsors of each partner)

- (Quarterly) Business Review Meetings (on a more tactical level to prioritise activities and to review progress. This is the main meeting organised and driven by the relationship managers to understand how the collaboration is evolving)

- Monthly Operational Meetings (various monthly operational meetings might occur due to different requirements, e.g. a Performance Review meeting, a Logistics executional meeting or a Customs Meeting. Ideally these meetings are linked with the S&OP – processes of the partners to ensure updated information are available and shared)

• Process Mapping

For information sharing, the information flows between all partners have to be mapped consciously to assure consistency and timeliness. This continuous mapping is the basis of the following process adaption at the different partners’ side which will be considered in more depth in the second part of the series.

• Commonly defined KPI‘s – measured regularly

Based on the vision and the corresponding targets, success of collaborative activities should be measured. This can either be in the form of realized hard cost savings or in the reduction of administrative workload or in an improved Customer Service through a quicker response time. Also soft aspects should be measured in form of regular surveys to understand which requirements are met and where improvements are necessary.

It is also important to use measures which cover cross – functional results to understand all consequences of the relationship. An example here is the impact of OTIF measures on Inventory levels. Performance Indicators should support long-term collaboration, the benefits should be documented.

- Have a regular pro-active communication so that no surprises occur on either side

- • Commonly agreed ways of working / incentives

-

It is essential to have common ways of working throughout the relationship. Incentives like gain sharing agreements will help to drive a continuous improvement culture. The benefits of collaboration should be fairly shared between the partners.

Picture 3. Commonly defined rules for ways of working during IT system integration projects.

Share information to strengthen collaboration

If these steps are taken, they will ultimately help mitigate the fear of information sharing and strengthen collaborative activities. They will also improve efficiency and create new opportunities for all stakeholders. Ultimately they will prepare the organization for a successful, long – lasting relationship with partners based on mutual trust and commitment in a continuous improvement culture.